home

diary |

|

History

of the Guitar Craft Plectrum

Firstly, some writing from Robert Fripp regarding the plectrum we use in Guitar

Craft:

"The plectrum guitar is a hybrid of the banjo and Spanish guitar which emerged in the dance bands of the 1920s. The main picking technique was based on a combination of banjo and mandolin technique, which developed with alternate picking during the 1950s. The electrification of the guitar during the 1940s took responsibility for tone and volume away from the pick and picking. A repercussion of this is the absence today of both a standard or generally accepted school of picking, and a standard design of pick.

The Guitar Craft pick is a relatively precise tool which goes with our orthodox approach to picking. My own guitar teacher was Don Strike, a virtuosic banjo, mandolin and guitar player whose background was in the styles and techniques of the 1930s. I began to develop this picking technique around 1959, and it became my specialty. The technique has become more refined and sophisticated since 1985, when the Guitar Craft courses began.

Briefly, the pick goes with the picking, and the picking goes with the approach to playing. Our approach to playing reflects how we live our lives. The Guitar Craft pick is precise, and the tone accurately reflects the manner in which we hit the string. If we hit the mark, the tone is true. So, if we wish to hear the accuracy with which we live our lives, this is a reliable pick. If we wish to rely on props, such as amplification and effects, this may or may not be the pick for us.

The original form of the pick was in tortoiseshell, and is not in india rubber. The manufacturer has now stopped production of this model, and sold us their remaining raw materials. We have taken on manufacture of the pick, primarily to make available to Guitar Craft students."

Written in 1988 for Guitar World magazine. Robert Fripp.

* * * * * * * * *

GC Pick Production History

by Steve Ball

June 1, 1988

Robert gave me one of his original Tortoise shell triangle picks (from Don Strike?) and a sample "Herdim" pick and asked me to research and go about manufacturing something similar.

June 7-30

I sent out some samples to rubber mfgrs. to learn more about the material which RF called "india rubber". There was no mention of "india rubber" in any technical literature. I visited about nine rubber manufacturers and injection molding specialists around the Boston area.

June 30

Little or no response - no one has ever heard of "india rubber" and most

pick manufactures are now using plastics.

July

Stumbled on to the term "ebonite" via research of combs made in the 20s out of "rubber imported from india." There were no internet or search engines in 1988. Went to MIT materials library; found volumes on "ebonite" formerly used to make bowling balls, pens, combs, jewelry. Ebonite is essentially vulcanized rubber - rubber with huge amounts of sulfur added. Very few countries use or manufacture this anymore.

July 15

Made contact again with "Gunther Dick" in Germany who made the original "Herdim" triangular picks, which were now no longer available -

in the late 70s, they moved over to nylon, and completely changed their

plectrum designs. No more symmetrical triangles. Ordered a catalog and samples. Heinrich Dick said he would research and find a name of his original supplier of the rubber sheets he used to stamp the

original Herdims.

Late July

Heinrich found a few remaining sheets of "ebonite" in a factory in the south of Germany - in the warehouse of his original supplier. I immediately ordered these and had them shipped to me in Boston.

August 15th

Received the sheets. 80mils thick. Picks need to be 40 mils thick. Heinrich called - he found a few more sheets. I ordered these too. I asked him about the thickness. He said they had to grind the thickness down to make the various Herdims (about 20 different sizes shapes and thickness' were offered over many years.)

September 10

More sheets arrive. Still way too thick. "This is as thin as we can make it" says the supplier. So, I still search for thinner sheets in the US and overseas. Prince Rubber in upstate NY has a few sheets. All too thick. I ordered them anyway.

October/November

After a month of experiments and searching, I found a "Grinding" company who

could "grind" the picks to the proper thickness (which is what Gunther Dick used to do). Experiments begin - it

works, but it is time consuming and expensive.

December

Production begins on the first batch of 500 picks.

December 15

500 triangles cut by Standard Tool and Die in Belmont MA.

December 15

Picked up, inspected and delivered to Centerless Grinding in Waltham MA.

December 19

Picked up and delivered ground pieces to Std Tool for "tumbling"

polishing (A two-week process, like rock tumbling).

December 28

Embossing process begins (heat stamping the logo in the center)

January 2, 1989

I visit std tool to inspect the first samples. Dreadful. Rough edges, emboss is unreadable and inconsistent.

Polishing is ineffective.

January 2-8

Tweaking the process. It is clear Std Tool cannot adequately polish the picks. This is not their specialty and they recommend that I find a specialty-polishing house. Centerless Grinding does not polish. The search begins for a tumbling house.

January 9th

Order 5000 picks to begin cutting by Std. Tool (to get the process going, even though I don't yet have a polishing solution...) Cut picks to be delivered by Feb 1st for Grinding, back for embossing by Feb 23,.. then polishing???

January-Feb

Experimented with home "rock tumblers" and search for tumbling companies who deal with rubber or plastic parts.

What a mess. Mid-Feb, found one in New Hampshire, again via the MIT library. Correspondence via snail mail, finally, they agree to do some tests on a few picks. Mid march - works fine, but reduces the thickness of the picks significantly! Too bad - a trade off. (hence, the thin unstamped GC picks we have been using for the past 10 years.)

March - May

The production process continues, eventually, 5000 picks are manufactured and delivered in three gauges: Thin (25mils), Medium (30mils) and Thick (35 mils). Only about 30 % of these are embossed with the logo to save $. The emboss process also destroys about 15% of the picks which do not set properly after the heating (curling problems).

Rough budget:

$1,600 materials (rubber sheets and shipping)

$3,100 tooling (triangle die cost and cutting)

$1,900 grinding to proper thickness

$1,600 embossing (each one embossed by hand with a custom heat stamper)

$ 900 polishing (three weeks turning in a tumbler with soft wood chips, in various batches of thickness)

_______

$9,100 Not counting any of my time or transportation costs.

* * *

Some of the general feedback from users of the first round of picks:

"close, but not as good as the Herdims."

"too thin"

"edges too rough"

"too expensive"

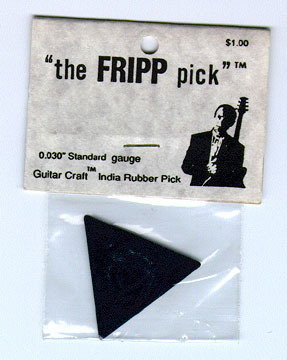

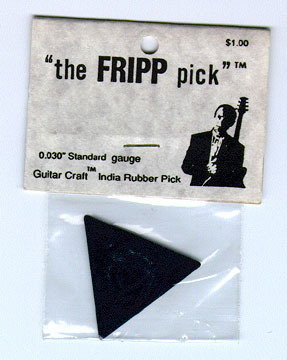

We were charging $1.00 per pick from the beginning, in an attempt to offset the

manufacturing costs, but clearly this was an act of service, not an act of commerce.

This early, bogus, marketing attempt was abandoned before it even hit

the streets...

None the less, these 5000 picks were sold out in about 1993 or

1994 via sales directly to Crafty guitarists. . Mark Perry at

Possible Productions was selling the last batch of these (aside from about 600 or so which I had set aside for

future GC courses.) These are now also gone. Since then,

various eager Crafties have investigated and researched new pick manufacturers over the past six years, but none have yet come up with a viable solution. At

some point, Jan

Ferguson in Los Angeles came up with a sculpted clear vinyl pick which was a proposed alternative.

This was abandoned as impractical to manufacturer.

At one point, a team on the East Coast were working on a solution (also clear plastic, I believe).

This also recently fell through as expensive and impractical.

At one point, someone in Brazil had a solution. At one point, someone in Japan was

also supposedly working on this (Hideyo recently told me this was abandoned as the

manufacturerr wanted $100,000 up front for tooling.)

About two years ago, I urgently sent some knotwork symbols to DGM who had a new manufacturer in Germany who was supposedly working on a new pick. About three months

later, DGM asked me to send a new copy of these symbols to the manufacturer again.

Apparently the originals were lost or misplaced. This process may still be

underway, but I doubt it.

Finally, now in early 1999, Patrick

Schuleit of the Washburn Guitar Corporation has undertaken a project

to create triangular picks based upon the original Herdim and GC

prototypes. Stay tuned for news about the results of his

work! Good luck Patrick!

* * *

I still maintain a small personal collection of Herdims, GC samples, prototypes, and competitors picks.

I gave my last small stash of GC picks to Robert in Chile in 1997 in

the hopes that something new might appear when this supply disappears.

Steve Ball, 1999

* * * Addendum, January 2003 A couple of months ago, I

received a kind letter and pick sample from Mr.

Michael Wegen in

the Netherlands, and share the sample with various Seattle Crafties.

The general consensus: okay, but not great.

The (passive) search for a new Guitar Craft pick continues.

* * * home |